The FLIT M2 is the optimal bike for the urban commuter.

The M2 features a compact fold, a fully integrated electrical system and weighing just 14kg, you can carry it, lift it, and ride it further.

I joined FLIT (a small Cambridge start-up) as a design engineer at the inception of the M2 project taking the bike from conceptualisation through to production. Designing the M2 we focused on creating a bike for the commuter market which was compact and lightweight without compromising the ride experience.

The outcome is a bike which features a weld-less frame, an anodised finish and a fold that takes less than 10 seconds.

Design

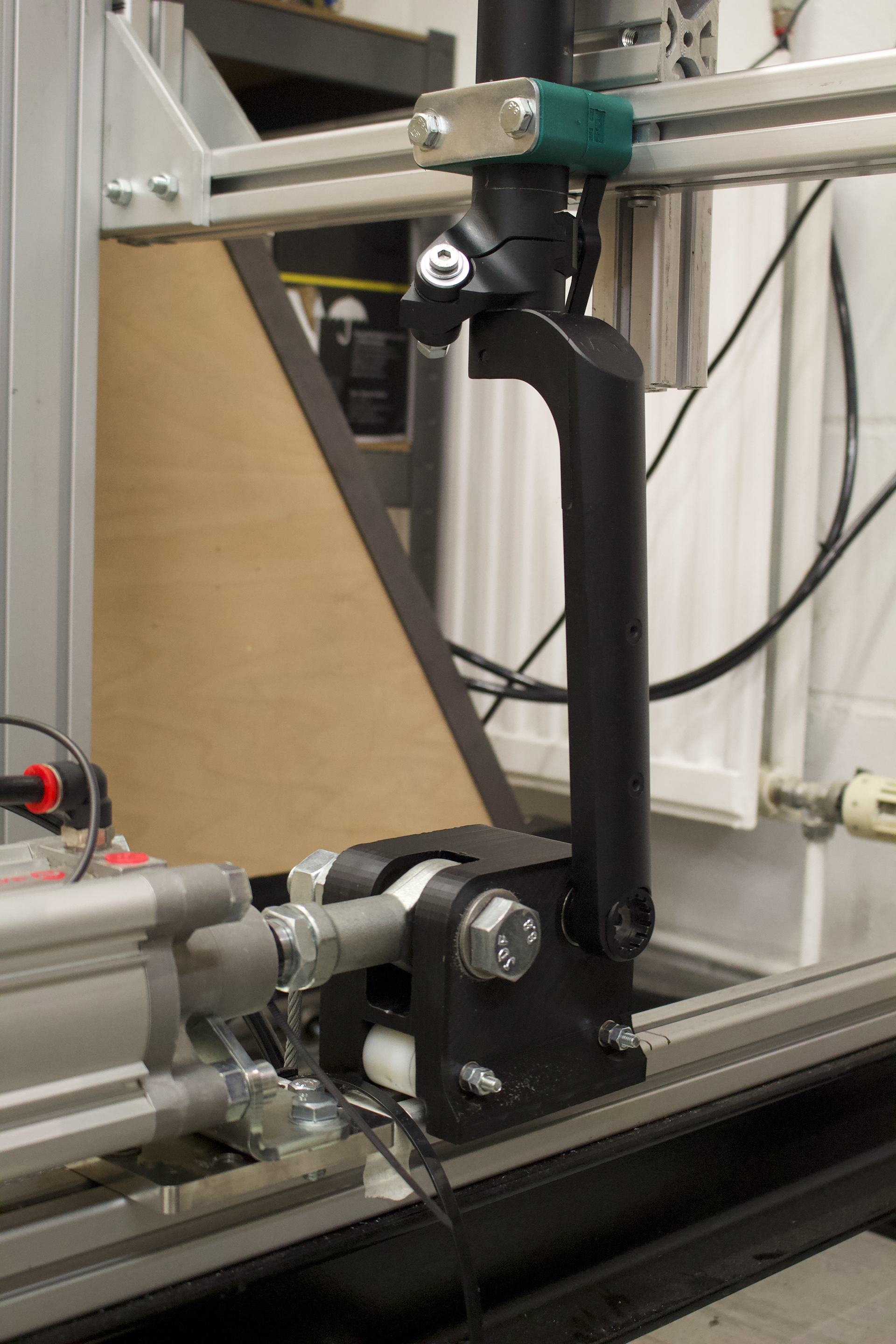

The front fork and hub sub-assembly was one of the areas in which I was responsible for the design, testing and manufacture. The single arm form was designed to be a key feature of the FLIT M2, with an eye-catching design whilst proving several functional advantages.

1. Compact Fold - Eliminating one of the forks reduces the width of the bike when folded to neatly fit everything into a small package.

2. Disc Brake - Secure Mount for disc brake allowing for slight adjustment for responsive and reliable braking.

3. Integrated Retaining Feature - Alignment of snap pin and rear swing arm to hold the bike securely while rolling, folding and carrying

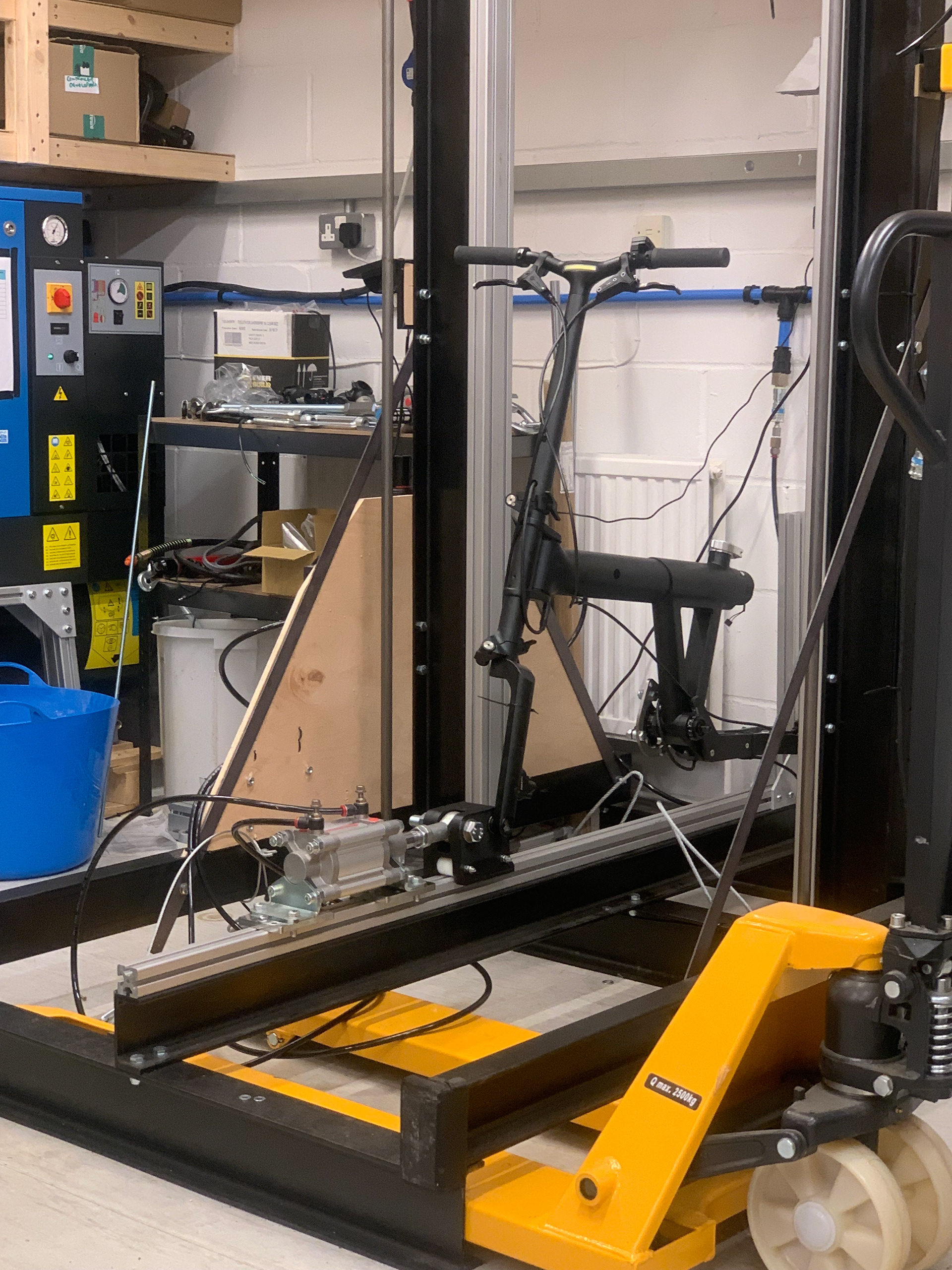

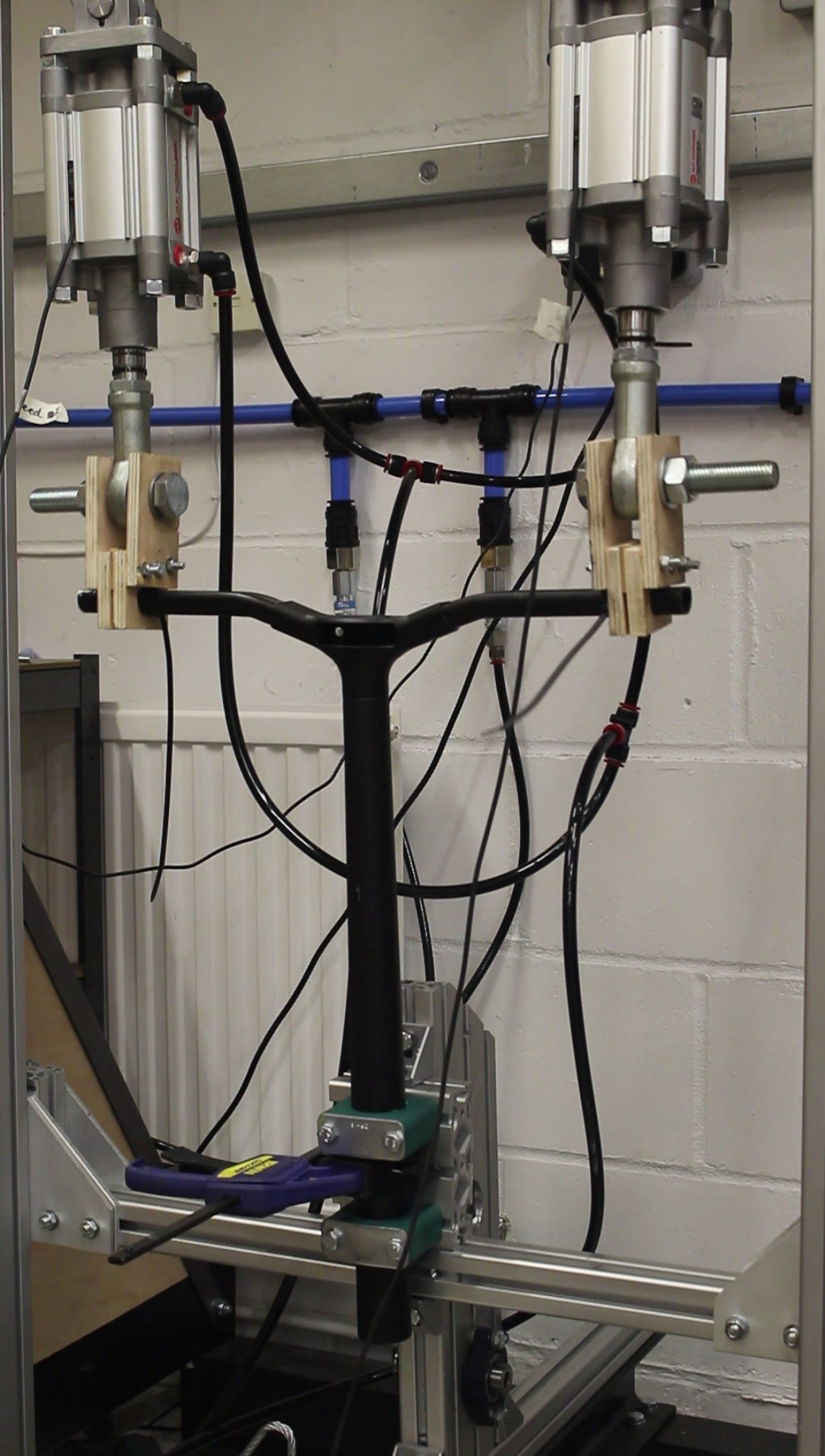

Testing

The bike has been designed to meet EN ISO 15194 and so the fork had to be put through a range of static, impact and fatigue tests. These were carried out in-house to speed up the design process, however, due to the custom nature of the parts each test had to be designed to match the fork and axle.

Several non-regulation tests were also conducted to meets internal bench marking and ensure the bike will last a long life in service without failure. Several of these test including using Arduino / Python programming to run fatigue tests and test environmental wear.

Accessories such as mudguards and kickstand are a critical aspect of the customer buying decision, however, due to the extreme requirements and constraints with the FLIT M2 all of the accessories were developed specifically for this bike.

Mudguards

The mudguards were designed to provide effective coverage when riding in wet weather and fold away to allow the bike to roll on its own wheel in the folding position.

Kickstand

The kickstand was designed to be a clean and neat accessory which follows the design of the FLIT M2 and folds neatly away when not in use.

Due to the skyrocketing lead time of welded frames we started the design of the M2 with a goal to design a folding e-bike which wasn’t manufactured using traditional tube stock and welding.

Straying from traditional bike manufacturing methods gave us access to a much greater number of manufacturers, factories, materials and processes. Having this flexibility and freedom had a massive effect on the final product which includes several features which were not previously possible.

Material

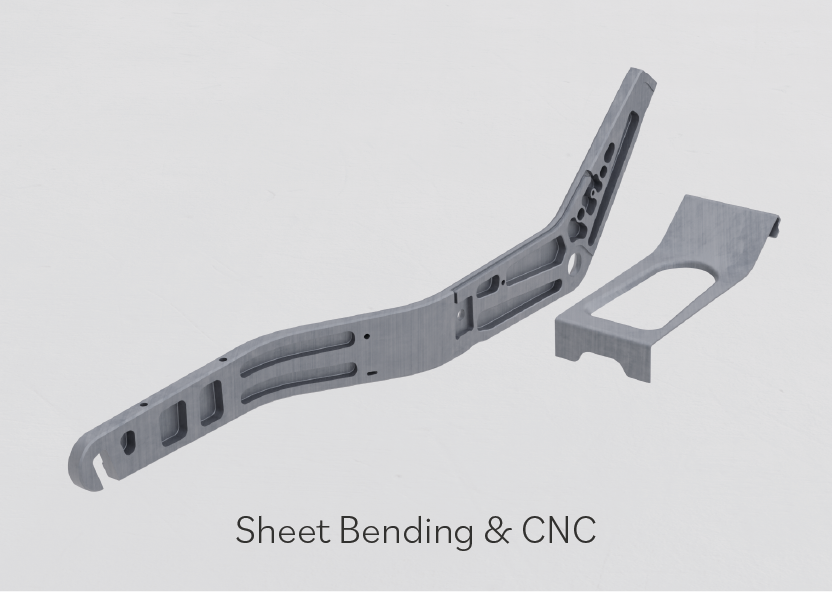

The FLIT M2 frame is made from several Aluminium alloys depending on the strength requirements and manufacturing processes of each part. The majority of the frame is made from 6061 for it strength, fatigue resistance and cost of material, for non-extruded sections where higher strength is needed 7075 was used and if the part was to be manufactured by sheet bending 5052 was the best option.

Finish

Using Aluminium allowed us to have an anodised finish across the bike frame, this is a very durable finish which provides a clean and aesthetic pleasing finish not currently seen in the bike market.

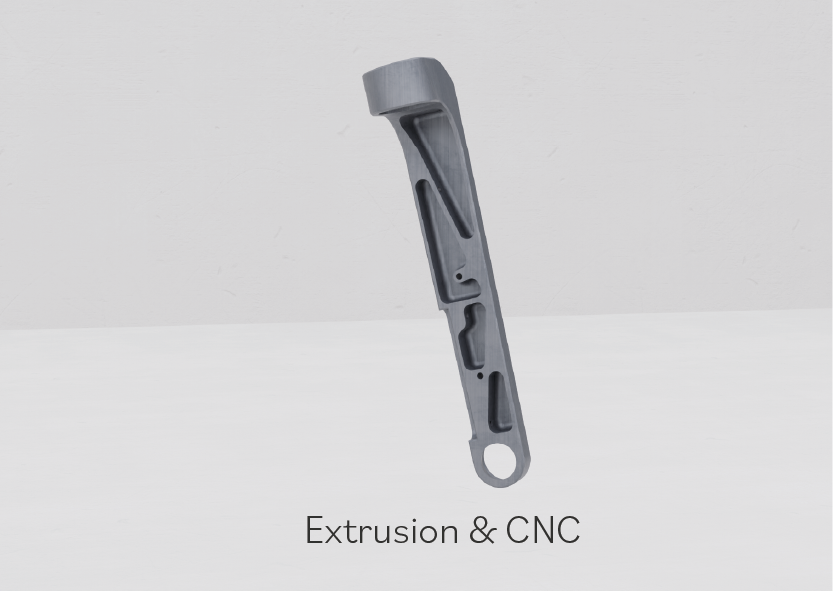

Processes

The majority of the FLIT M2 frame is manufactured through extrusion, CNC machining, rotary swathing and sheet bending with the plastic parts made from injection or compression moulding. These manufacturing processes were selected due the cost at batch production volumes, however, the majority of the parts are designed to transition to forging, casting and hydroforming as volumes increased.